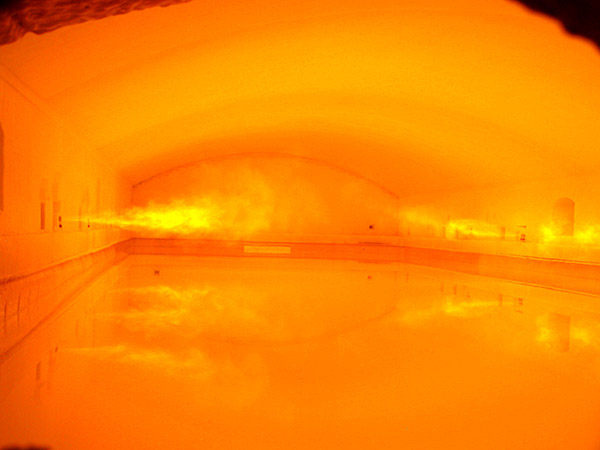

A leading company in Turkey’s glass industry has taken a decisive step toward optimizing its industrial processes by installing oxygen and temperature measurement probes in several of its melting furnaces. This initiative is part of an ambitious technological modernization plan aimed at improving energy efficiency, reducing emissions, and ensuring greater consistency in the quality of the glass produced.

The OPTIMA® XV analyzers, developed with cutting-edge technology, enable continuous and precise monitoring of the furnace’s internal conditions. Thanks to real-time measurement of oxygen levels and temperature, technicians can dynamically adjust combustion parameters—resulting in lower fuel consumption and a significant reduction in pollutant gases.

✅ Key Advantages of the OPTIMA® System:

- More precise control of the melting process

- Improved glass homogeneity

- Reduced energy costs

- Extended furnace lifespan

These types of solutions are gaining traction in the global glass industry, as energy efficiency and carbon footprint reduction become top priorities for manufacturers.

📩 If you’re interested in optimizing and improving your thermal processes, feel free to contact our technical-sales department at levante@oxycomb.com so we can evaluate your case.

#EnergyEfficiency #Glass #Combustion #OPTIMA #EnergySavings #OxycombSistemas #ProcessControl