OPTIMA SYSTEM®

CONTINUOUS MEASUREMENT AND ANALYSIS OF COMBUSTION GASES

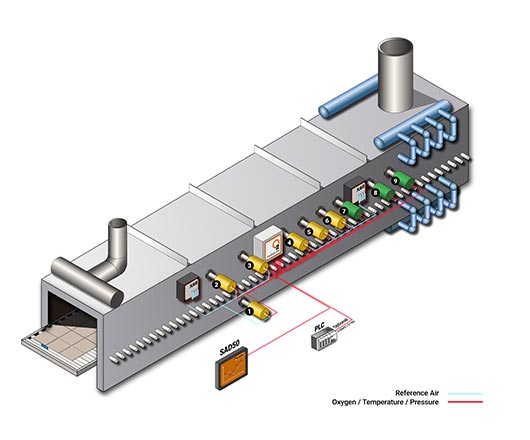

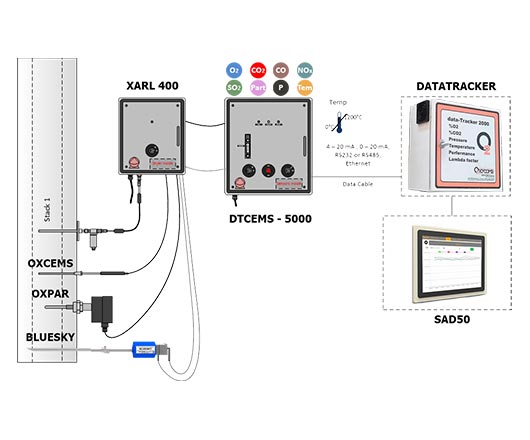

The OPTIMA® System allows continuous, in situ and real-time measurement of any influential gas in an industrial combustion process. Depending on each application, it consists of the following elements:

Assembly diagram of the OPTIMA® combustion control system

Assembly diagram of the OXCEMS® emissions control system

ANALYZERS

OPTIMA® / BLUESKY® / OXCEMS®

The analyzers manufactured by OXYCOMB Sistemas measure continuously and in situ the combustion gases from inside the kiln chamber, dryer, boiler or chimney / channeled emission source. Depending on each model, O2%, CO2%, CO, NOx, SO2, CH4, C%, flow, speed, particles, temperature, relative humidity, pressure or others can be measured.

PANELS AND SWITCHBOARDS

The panels and switchboards manufactured by OXYCOMB Sistemas collect the signals from the OPTIMA, BLUESKY and OXCEMS analyzers of O2%, CO2%, CO (ppm or mg/m3), NOx (ppm or mg/m3), SO2 (ppm or mg/m3), CH4 (ppm or mg/m3), particles, flow rate, speed, etc.

REQUEST MORE INFORMATION

If you are interested in our combustion control systems, do not hesitate to contact us. Our team will advise you to improve the efficiency of your combustion processes.