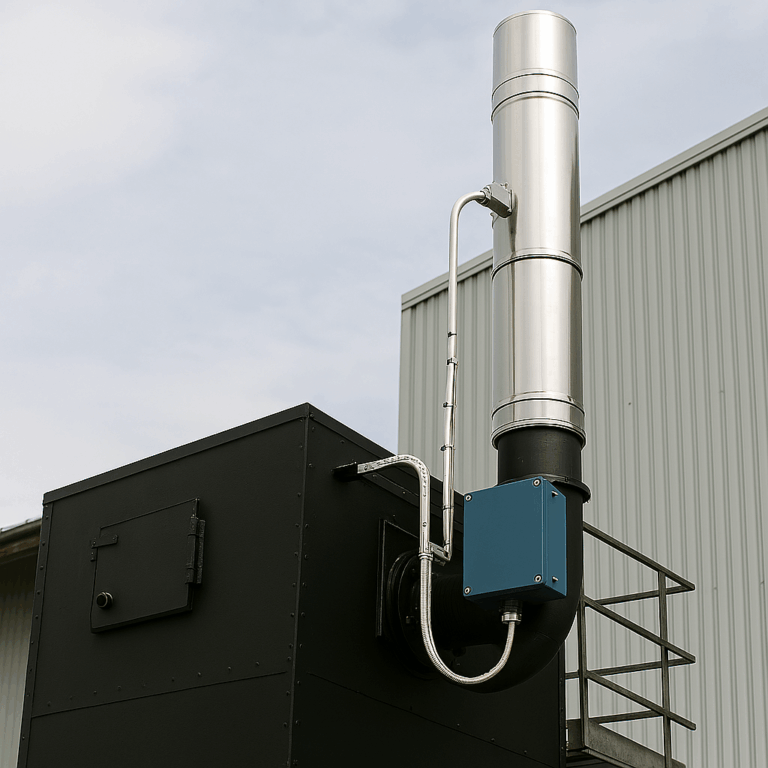

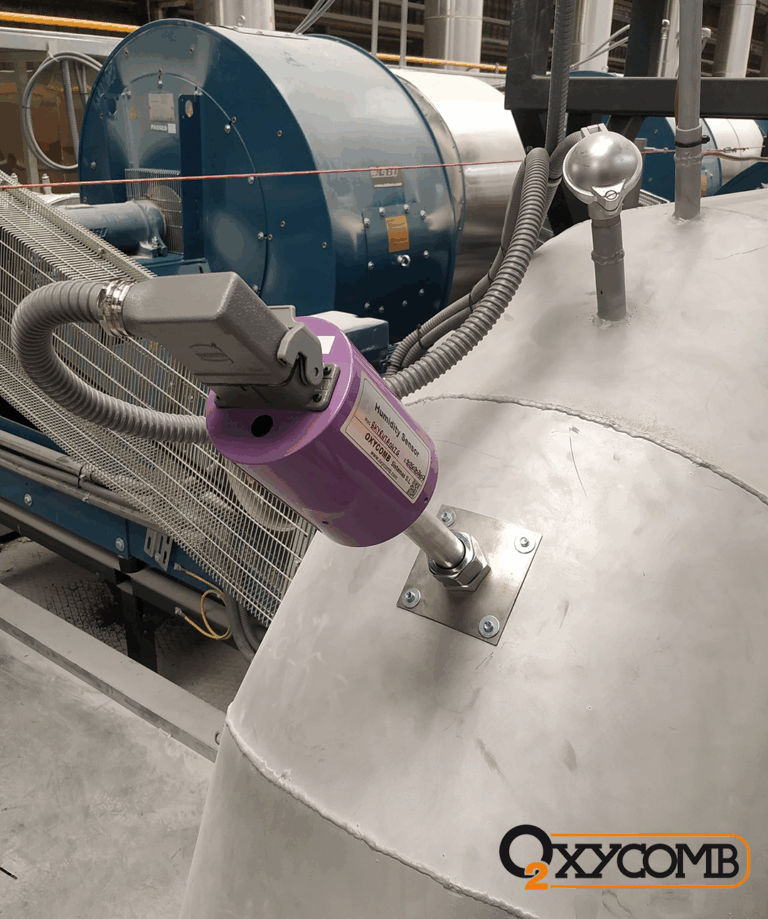

Cerámica del Nalón, an international company based in Asturias and specialized in refractory ceramic products, has implemented the OPTIMA® and OXCEMS® systems in one of its tunnel kilns, aimed at a more precise control of the combustion atmosphere.

This technological improvement will allow the company to achieve significant energy savings, which will directly result in reduced gas and electricity costs. Additionally, the more accurate adjustment of the firing process parameters will help to:

- Improve the quality of the final product

- Reduce atmospheric emissions

- Optimize the kiln’s operational efficiency

Among other actions carried out by OXYCOMB, notable improvements include the incorporation of control loops in the smoke and combustion air extraction system and the installation of an air vein burner to ensure a constant temperature in the dryer. These solutions directly contribute to more efficient kiln regulation.